How Researchers and Universities Use Induction Heating

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

11/18/19 1:59 PM

A company that manufactures, sharpens, repairs and modifies tooling turned to THE LAB at Ambrell. They were torch brazing carbide inserts into tubes but needed a more consistent heating method. They manufacture modest quantities of parts so their concern was quality of the joint, not heating time.

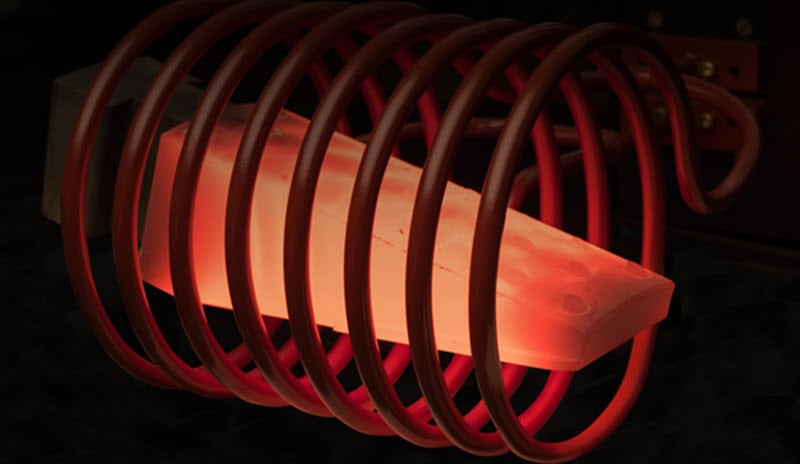

It was determined that an EASYHEATTM 2.4 kW, 150-400 kHz induction heating system would be the right system for this application. A custom-designed single position multi-turn helical coil was built to generate the required heat for the application. The part needed to be heated to 649 °C (1200 °F). It took approximately four minutes to heat the assembly to temperature and braze it uniformly.

The application achieved the client's objective of receiving consistent, repeatable heating. Torch heating is dependent on operator skill and consistency, so induction offers a considerable advantage. Additionally, induction is precise and doesn't introduce unnecessary heat into the work environment. The end result was that brazing with induction prevented defects that the client was seeing with torch heating.

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

Objective A company had been using a flame for brazing copper assemblies to make electrical components, but they contacted THE LAB at Ambrell because...

Induction heating is a highly efficient and versatile technology with numerous industrial applications. Unlike traditional heating methods that rely...