Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

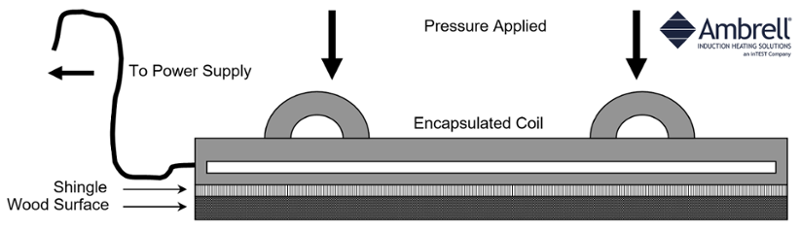

A client needed to heat the stainless-steel substrate of a solar panel shingle in order to melt the polymer encapsulant, allowing two shingles to bond together.

More induction bonding application notes

THE LAB at Ambrell determined that an Ambrell EASYHEATTM 1.2 kW, 150-400 kHz induction heating system would work well for this bonding application along with a workhead and coil specifically designed for this application. The assembly needed to be heated to 266 ºF (130 ºC).

Initial tests were conducted to optimize the power delivered to the part. Stationary heating, with the coil located on the topside of the sample, was utilized to achieve uniform melt and adhesion. The shingles were overlapped according to client requirements and placed on wood to simulate installation. In addition, pressure was applied by pressing the water-cooled coil against the shingle to facilitate the bonding (see illustration above). Tests were performed at several time-voltage settings. Testing resulted in excellent bond formation with the absence of encapsulant bubbling and only slight surface texture change.

Induction heating offers several benefits for bonding applications when compared to other heating options. First, with induction heating is fast, so it accelerates the production rate/throughput when compared to many other methods. It also delivers consistent, repeatable heat time after time, which is extremely beneficial from a quality perspective. Finally, thanks to THE LAB's expertise, the client was provided a solution that met their unique requirements.

If you have an application that might benefit from parts testing, contact THE LAB to take advantage of free induction heating application testing from our expert applications team. Additionally, we have Virtual Lab Service so you can observe testing live from your office. And, whether you choose Virtual Lab Service or not, we'll always send you a video, lab report and your parts after testing so you can assess the results before deciding on purchasing a system.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...