Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A client contacted THE LAB at Ambrell to heat magnetic steel strips to 1,400 °F (760 ºC) in under one second for an annealing application.

More induction annealing application notes

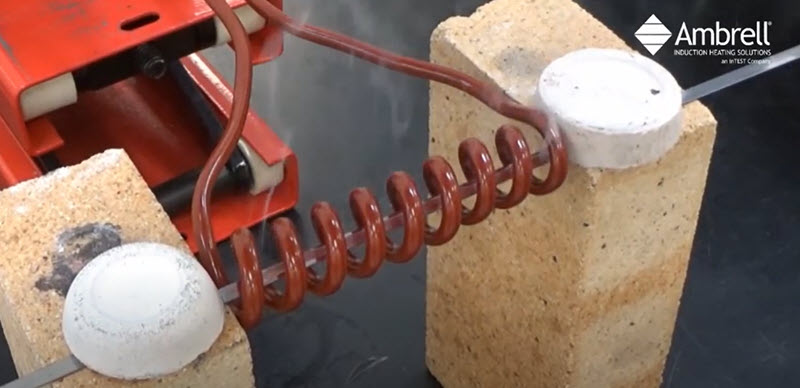

THE LAB determined that an Ambrell EASYHEATTM 9 kW, 150-400 kHz induction heating system with single position multiple-turn helical coil would be the right solution for the client.

Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paint was then applied to a five-inch segment along the part, which dissolves when the part reaches target temperature. It took 0.8 seconds to heat the sample to 1,400 °F (760 ºC), which exceeded the client’s goal.

Induction from Ambrell is the preferred heating method for annealing for many organizations for several reasons. First off, induction is a rapid heating method, which can result in increased throughput. Additionally, induction delivers superior repeatability so the client will get the same result time after time. That repeatability can result in improved product quality. Induction is also hands-free and flameless, which enhances workplace safety. Finally, the expertise of THE LAB with our free induction heating application testing was important, as this solution meets the client's objectives.

If you have an application that could benefit from induction heating, you should consider free applications testing, including our convenient Remote Lab Service. With Remote Lab Service, you can observe testing in our laboratory from the comfort and convenience of your office.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...