Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

Injection-molded plastic parts are used increasingly in industry, particularly automotive, because of their strength and reduced weight when compared to metal.

The development of glass-filled plastic materials is undeniably the major cause for this increase. Manufacturing and other related processes must differ from conventional lower-temperature thermoplastic manufacturing methods due to higher melting temperatures.

In addition to the glass-filled plastics, there are many other components that use regular thermoplastics. Thermoplastics are still too soft to sufficiently hold a thread, so brass- or steel-threaded inserts are commonly used as anchors. Post-molded installation is more cost effective than molding in place, and induction is a proven way to preheat these inserts prior to installation.

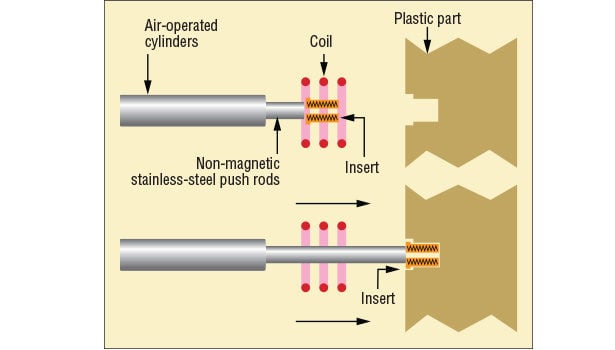

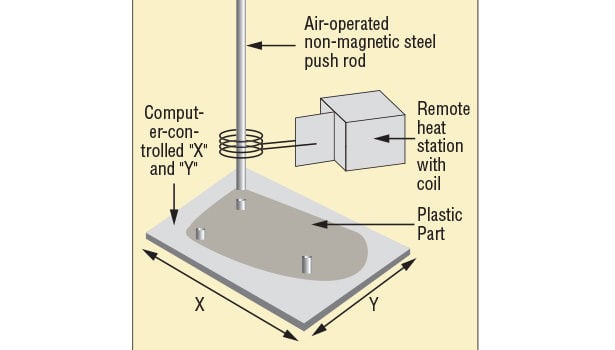

For heat staking, or indirect induction heating, the insert is preheated with induction and then pressed into a hole in the plastic part. This is accomplished by positioning the induction coil over the hole and then holding the insert in the coil for a short period of time. When the correct temperature is achieved, the insert is pressed into the plastic (Fig. 1). A narrow zone of plastic then melts and flows into the knurls of the insert. The plastic re-solidifies, resulting in a complete assembly that often has much better mechanical properties than inserts implanted with other techniques.

Figure 1 - Typical Heat Insertion Process

The insert material is usually brass or steel; each has advantages and disadvantages. Brass is non-magnetic and will not corrode as easily as steel. However, brass is a softer material and will anneal at temperatures as low as 450°F (232°C). Steel starts to anneal at 1200°F (650°C). Glass-filled plastics require inserts to be heated to 700°F (371°C) for correct installation, so the brass inserts must be heated and inserted quickly to prevent thread annealing. Brass has lower electrical resistivity than steel and, therefore, requires more power to heat with induction. The selection of the insert material is dependent on the specific application requirements, but brass is most commonly used in the industry.

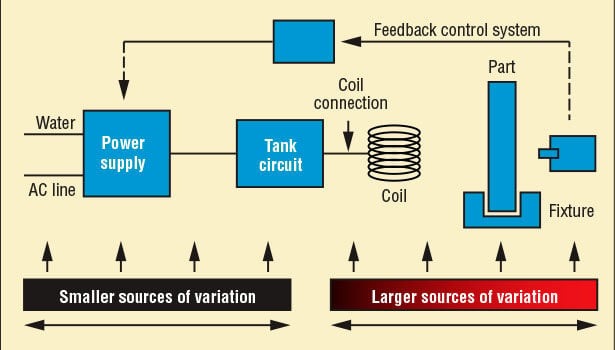

A basic induction heating setup is shown in Fig 2. It consists of a high-frequency power supply that takes the input from the AC line mains. This power-supply unit converts regular line frequency (50 or 60 Hertz) to a high-frequency signal, which operates between 10 and 400 kHz. This high-oscillating signal is then fed to a tank circuit that feeds the water-cooled induction heating coil. The signal generates a high-frequency magnetic field inside the induction coil. The insert is placed inside this induction heating coil. It generates eddy currents due to the high-frequency magnetic field and produces heat. An optional noncontact temperature controller can be used to measure the temperature of the insert. Its output can then be fed to the induction heating power supply to control the temperature of the insert for each cycle.

Figure 2 - Typical Induction Heating Setup

Tuning frequency: The frequency of operation of the power supply should be chosen to deliver efficient energy based on the size and material of the part. Care must be taken to ensure that this frequency is above the critical frequency of the part for efficient heating.

This is the cycle-to-cycle repeatability of the induction power supply in manufacturing given standard incoming voltage variations and other tolerances.

This should be the same every cycle to reach the same temperature on the insert.

This is dependent on the fixturing and handling device. Varying placement of the insert inside the induction coil will result in inconsistent temperatures of the insert.

The location of the insert in the hole of the plastic part is determined by insert pressure. Lower pressure leaves the insert above the required location, whereas higher insertion pressure may cause undesirable “flash” of the plastic material.

The diameter of the insert hole must be the correct size to allow the plastic to flow around the insert. If the hole is too small, extra plastic will be displaced.

Cool down following the insertion cycle is needed to anchor the insert inside the plastic part. If the cool-down time is too short and the insertion pressure is removed quickly, inserts will often be pushed out of the plastic part.

The installation temperature of the insert is a key factor in the success of the staking process. Each insert must be heated to the same temperature in the same time to achieve a consistent process.

The simplest system consists of a single-position heating coil to heat one insert at a time. Depending on the number of inserts in the plastic part, either the plastic part can be indexed under the induction coil or the heating head can be moved to each insert location. An x-y positioning table can be used in conjunction with a single-position coil when multiple inserts need to be installed in a single molded part. The position of the coil is held constant, and the x-y table moves each insert location under or above the coil. This technique provides for a flexible manufacturing tool that can be changed by software programming rather than hardware tooling changes.

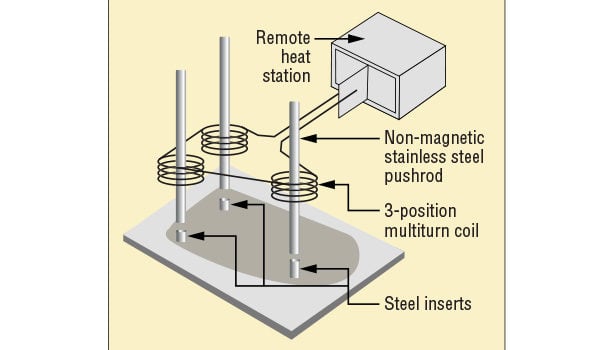

A second option for a single-position coil is the use of a robotic arm. The plastic part is held in a fixed location while the coil and indexing mechanism can be moved to each insert location. Location of the coil relative to the heat station is custom-designed for each application (Fig. 3).

Figure 3 - Single Position Heating Systemp

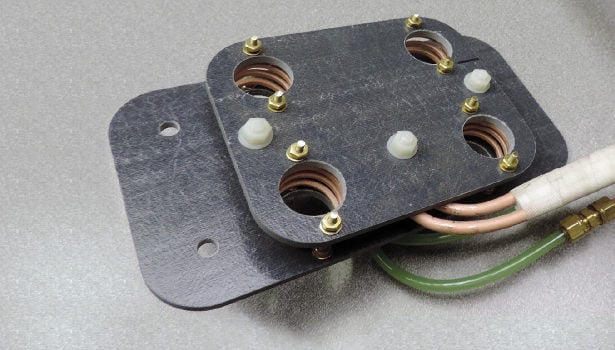

A multiple-position coil makes it possible to install more than one insert at a time into a single plastic part (Fig. 4). Three- and four-position coils have been used for this application. The coil is normally in a fixed position, and the plastic part is placed under the coil. The inserts for each location are heated simultaneously and then pressed into the plastic. The multi-position coil requires a higher power than a single-position coil. However, the production cycle time is significantly shorter.

Figure 4 - Multiple Position Heating System

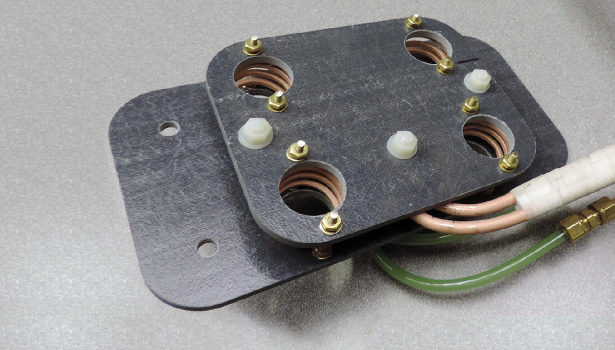

A four-position induction heating coil (Fig. 5) is used to heat four brass inserts of 8 mm diameter to 550°F (290°C) using the Ambrell EASYHEAT 7590, a 7.5-kW induction heating power supply. The inserts are heated to temperature within four seconds before they are pushed into the plastic part. The induction coil is designed to allow for adjustment of each heating location so as to heat the four inserts to exactly the same temperature. The temperature variation between the four positions of the induction coil, once adjusted, is locked to ensure good product. Figure 6 shows the thermal image of the four inserts at the end of the heating cycle.

Figure 5 - Four-Position Insert Heating Coil

Whether applied directly in an initial design or incorporated into an existing process or industrial heating operation, induction heating has become more and more desirable because of its ability to contribute to lean-manufacturing setups. It is easy to justify a good value proposition for the induction heating setup. Its flexibility, small size, versatility and efficiency represent an indispensable adjunct for a number of process heating applications in manufacturing processes worldwide.

Note: This article, written by Dr. Girish Dahake, was originally published as a cover feature in Industrial Heating (which has ceased publishing) via a submission from Ambrell.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...