Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A client requested complimentary application testing from THE LAB at Ambrell for a preheating for forming application. They had been using a torch, but were interested in switching to induction heating due to the speed and repeatability that it offers. They needed to preheat an area around an elliptical hole in a large steel tube prior to forming. The target temperature for the application was 1800 °F (982 °C).

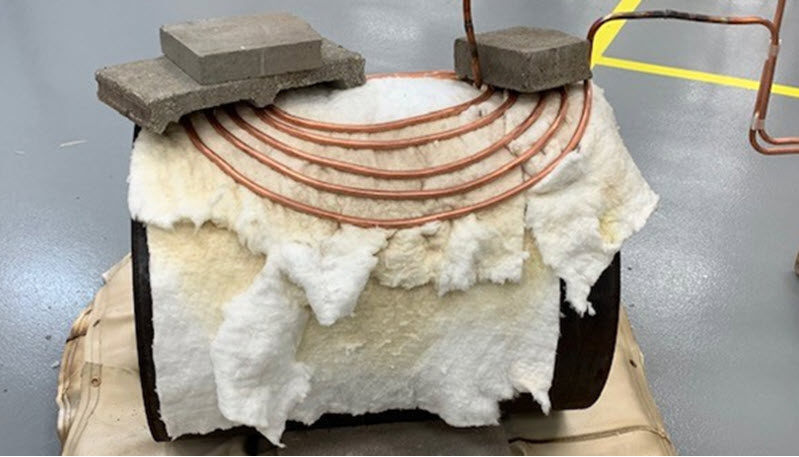

THE LAB determined that an EKOHEAT® 150 kW, 5-15 kHz induction heating system would be the right system for their requirements. They designed a custom single position, multiple-turn pancake coil for the application. Initial tests were conducted to optimize the power delivered to the part. The coil was separated from the part by two layers of insulating felt. The coil needed to be weighted down with cinder blocks to prevent levitation and an optical pyrometer was used to measure the temperature of the inside of the part. It took about 40 minutes to reach 1800 °F (982 °C), achieving the client's objective.

The client realized a considerable heating time advantage with induction heating. Additionally, induction is more precise than a torch tends to be as it is less dependent on operator skill. It is also more repeatable. Finally, induction is also more efficient as it introduces less heat into the work environment, while also not introducing an open flame into the work place. These are just some of the advantages of induction heating.

If you have an application you'd like assessed, contact THE LAB to take advantage of complimentary induction heating application testing from our team of induction application experts. When you decide to send your parts to THE LAB, you'll receive a laboratory report and a video of the testing, and you can even visit THE LAB during testing.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...