Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A client came to THE LAB at Ambrell needing to heat a 0.85” (21.6 mm) outside diameter magnetic steel tube to temperature to melt plastic handles onto metal broom poles. A rate of 25,000 parts per eight-hour shift was desired, with two parts heated at the same time inside the coil. THE LAB determined that an Ambrell EKOHEAT® 15 kW, 50-150 kHz induction heating system would be the right solution for this application.

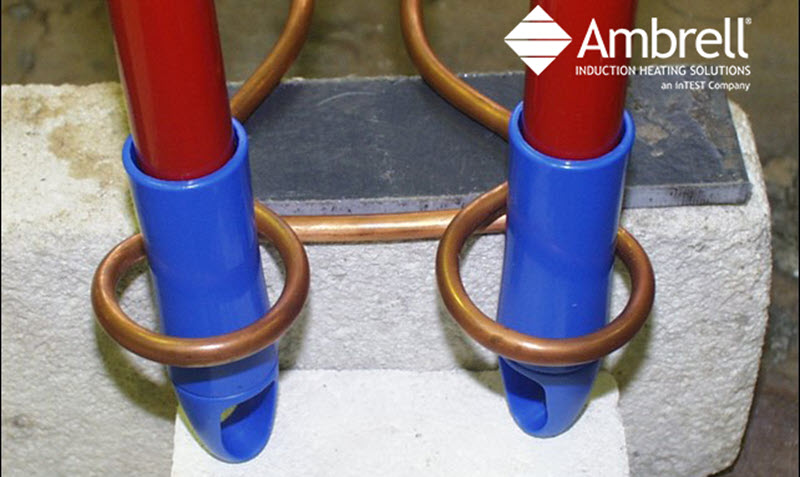

For testing, plastic caps (handles) were placed on steel tubes (broom poles). The two tubes were inserted into the two-position coil and heated for 800 milliseconds. The tubes were then removed and set aside to cool. Once the tubes had cooled, the plastic caps were pulled by hand to ensure they had melted onto the tubes as desired. The handles had in fact bonded to the broom poles. The overall cycle time of the process was 1.8 seconds (800 milliseconds of heating, and 1 second for the parts to cycle), which would enable the customer to exceed the desired production rate of 25,000 parts per hour.

The customer came to Ambrell because they were using an old, unreliable induction system from another company and couldn't find replacement parts. So a modern, quality system that maximized uptime was critical to them. Induction heating enabled them to have a high production rate of 25,000 units per eight-hour shift. Finally, THE LAB at Ambrell was able to design a solution that worked for them using less power than their old system, helping them gain efficiency.

If you have a heating application, be sure to take advantage of complimentary feasibility testing from THE LAB at Ambrell. We offer Virtual Lab Service, in-person testing, or you can opt to receive a lab report and video of the testing. Contact us today if you'd like to get started.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...