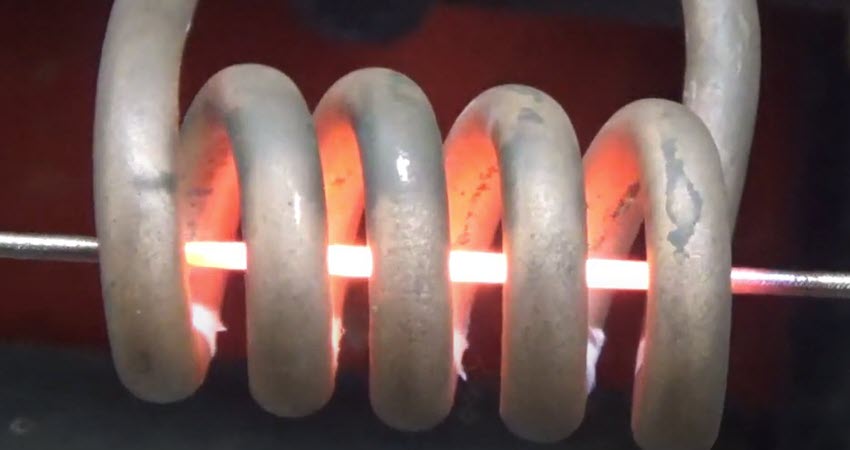

Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

Annealing, a heat treatment process, softens metals by altering their internal structure, making them more workable. But traditional methods like flame annealing can be cumbersome and lack precision. Consequently, many companies have found switching to induction annealing to be advantageous.

Let's look at why you may want to consider switching to induction heating for your annealing process:

Unlike a furnace that heats everything inside it, induction allows you to focus heat on specific areas of the metal. This is ideal for components where only certain sections need annealing, preserving the desired properties in other areas.

Induction heating boasts rapid heating cycles compared to traditional methods. This translates to quicker turnaround times and increased production efficiency. No more waiting for the furnace to preheat.

Induction heating provides control over the annealing process. You can precisely regulate temperature and heating profiles, ensuring consistent results and minimizing the risk of overheating or under annealing.

Induction heating eliminates the need for harmful fumes and combustion products associated with flame annealing. This creates a safer work environment and reduces your environmental footprint.

Induction heating promotes uniform heating throughout the targeted area, minimizing the risk of distortion and warping that can occur with uneven heat distribution.

Induction heating effectively anneals a broad spectrum of metals, from ferrous alloys like steel to non-ferrous materials like copper and aluminum.

With precise control, induction annealing ensures consistent results every time, eliminating the inconsistencies inherent in more manual processes, like flame heating.

In summary, if you're looking for a faster, more precise, and cleaner approach to achieve optimal metal properties, then you should consider induction heating. Ambrell offers free applications testing from THE LAB, so test your annealing application and see if induction heating could be a fit for your process.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...