Curing Material on an Aluminum Mandrel

Objective Heat a customer supplied aluminum cylinder to 80-120°C for a material curing application. More application notes

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

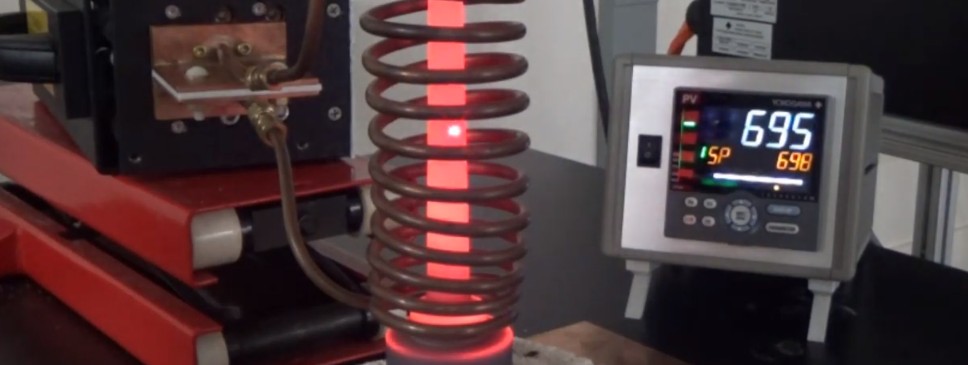

In the latest induction heating application video from THE LAB at Ambrell, a steel mandrel is preheated for a hard facing application with an Ambrell EKOHEAT® induction heating system and a custom-designed helical coil. As you can see in the video, heating the steel mandrel took just over one minute.

Induction heating offers a number of benefits for this application including speed, safety (no flame) and repeatability. If you'd like to get your parts tested in THE LAB, just fill out this form to get started. Alternatively, you can click here to check out more application videos, or click the image below to read an array of heating application notes.

Objective Heat a customer supplied aluminum cylinder to 80-120°C for a material curing application. More application notes

In today’s manufacturing landscape, efficiency, precision, and sustainability are critical. Induction heating—a process that uses electromagnetic...

When it comes to many manufacturing processes, including this forging application, precision and efficiency are critical. Traditional heating methods...