How Researchers and Universities Use Induction Heating

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

11/5/19 10:25 AM

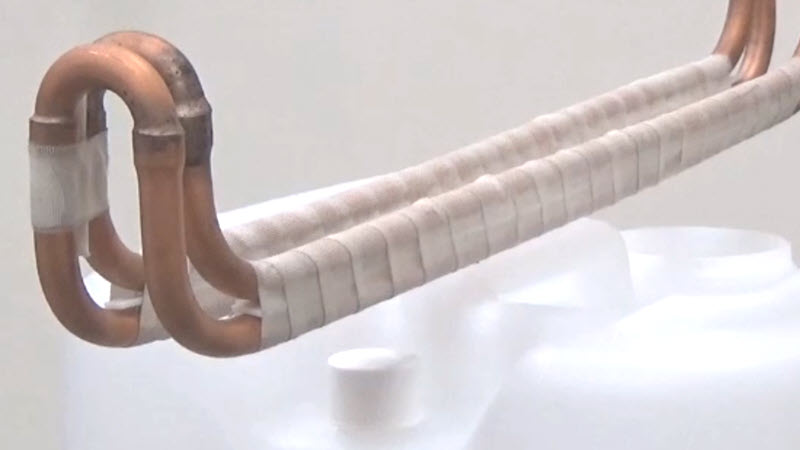

In the latest application video from THE LAB at Ambrell, a cap sealing application is tested. Cap sealing with induction is a non-contact heating method that welds the foil laminate to the lip of the container, commonly plastic or glass. In this case, the client had been using a cap sealing device that wasn't delivering enough power for this large plastic container, so the heating wasn't fast enough to meet their throughput requirements. Consequently, they turned to THE LAB for a proper induction solution.

THE LAB designed a channel coil that would work well as large containers passed underneath it. It was designed so the heat from the coil would heat the seal and the pressure from the cap would tighten it and seal it to the bottle. One second was the time the container had to pass underneath the coil and THE LAB's testing proved that would be sufficient to perform this cap sealing application. Now, take a look at the video:

Visit our cap sealing application page to learn about other cap sealing applications assessed by THE LAB at Ambrell. And, speaking of THE LAB, be sure to learn more about the free induction heating application testing they offer.

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

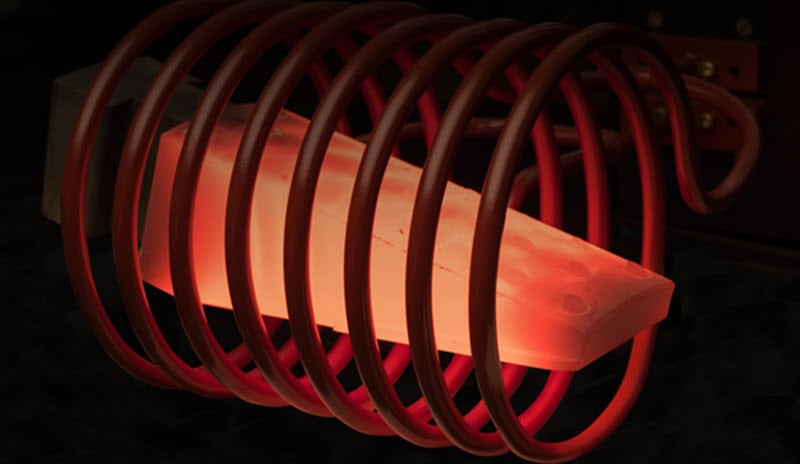

Objective A company had been using a flame for brazing copper assemblies to make electrical components, but they contacted THE LAB at Ambrell because...

Induction heating is a highly efficient and versatile technology with numerous industrial applications. Unlike traditional heating methods that rely...