How Researchers and Universities Use Induction Heating

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services: More

Learn:

Learn: More

About:

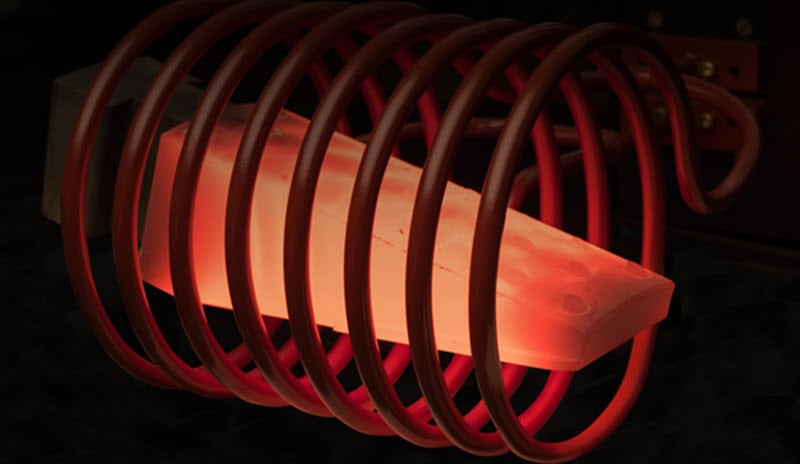

A manufacturer of metal powders needed to harness the benefits of induction to melt iron powder. They turned to THE LAB at Ambrell to design a solution to melt 45 grams of iron powder within 80 seconds. Applications engineers designed a single position, four turn helical induction heating coil for the application and determined an Ambrell EASYHEAT 6 kW induction heating system would heat the iron powder in the ceramic crucible in less than 75 seconds.

Benefits of induction melting for this application include fast, non-contact heating, repeatability and the minimal footprint of the EASYHEAT. Additionally, THE LAB was able to design a coil and determine the perfect system for this application. The client received a video of the complimentary applications testing to see the application in action prior to purchasing a unit.

To learn more about induction melting and view other application notes from Ambrell, visit our website. To request free applications testing from THE LAB, fill out our lab service request form.

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

Objective A company had been using a flame for brazing copper assemblies to make electrical components, but they contacted THE LAB at Ambrell because...

Induction heating is a highly efficient and versatile technology with numerous industrial applications. Unlike traditional heating methods that rely...