Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

11/29/17 11:32 AM

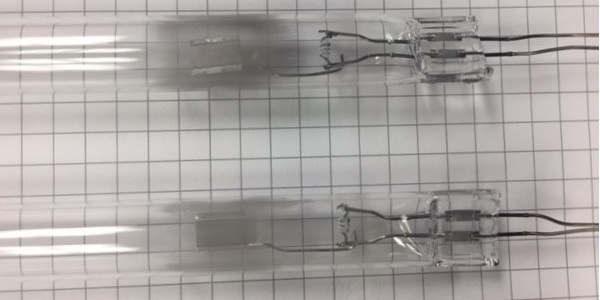

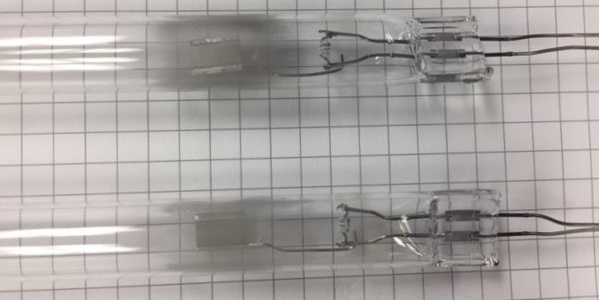

A manufacturer in the lighting industry needed to heat lighting tubes for a getting firing application. Getter heating removes residual gas from bulbs during manufacturing. Initial testing confirmed that an EASYHEATTM 4.2 kW, 150-400 kHz induction heating system equipped with a remote workhead was the right system for the application.

THE LAB at Ambrell conducted testing for the client to prove out the application. The bulb was heated until the getter was glowing and the coating vaporized and condensed on the inside of the bulb. It took 10 seconds to heat the sample to temperature, meeting the client’s process requirement.

The expertise of THE LAB at Ambrell, induction's repeatability and the EASYHEAT's modest footprint played into the client's decision to turn to Ambrell. Ambrell's reputation for quality, including systems being backed by two-year warranties, also factored into why the client chose Ambrell.

Click here to learn about other heating applications that THE LAB at Ambrell has designed. Interested in getting your application tested by THE LAB? Just fill out this form to get started!

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...