Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

3/28/17 3:22 PM

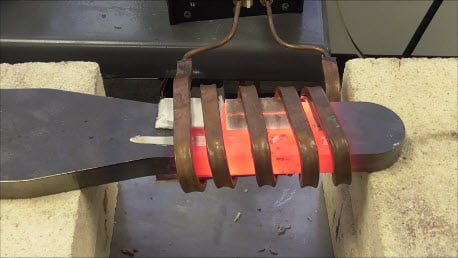

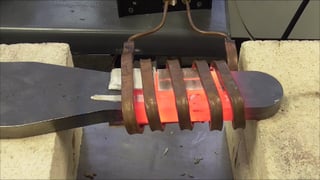

A client came to THE LAB looking to improve upon their heating process. They had been using a torch, but wanted a faster, safer, more repeatable method of heating. The objective of the application was to heat a magnetic steel part to 1700 ºF (927 ºC) for a forming application.

THE LAB determined that an Ambrell EKOHEAT 15 kW/50-150 kHz induction heating system would be optimal for this application. A specially designed single position multiple-turn helical coil was leveraged. Testing showed that heating to the targeted through-Curie temperature would take two minutes and twenty seconds.

The client benefitted from speed gains with this induction heating process along with greater safety and enhanced repeatability. And thanks to the expertise from THE LAB, the client knew exactly how induction would work with their application prior to making a system purchase.

Interested in learning about other forming/forging induction heating applications? Check out our application library and see how others have benefitted from the expertise of Ambrell's applications experts.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...