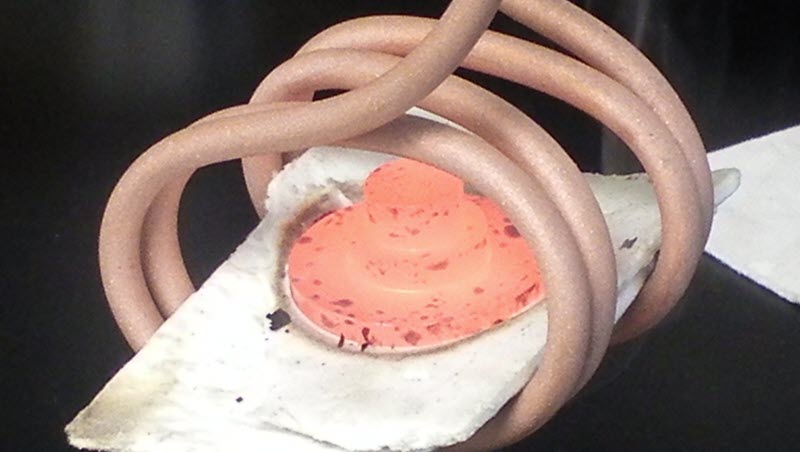

Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

A client attempted to cold forge a steel part with a flange, but wasn't getting the desired results. Consequently, they turned to THE LAB at Ambrell to see if hot forging would meet their time and quality objectives. Their goal was to heat the part to 1800 ºF (982 ºC) within 30 seconds.

A specially-designed single position multiple-turn helical coil was designed by THE LAB for this application. Heating took approximately 20 seconds, which was 10 second less than the client's goal. An Ambrell EASYHEATTM 5kW induction heating system was used for this application.

Induction heating's rapid speed, precision and Ambrell's ability to design a tailored solution thanks to complimentary applications testing from the experts atTHE LAB led the client to choose Ambrell.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...