Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

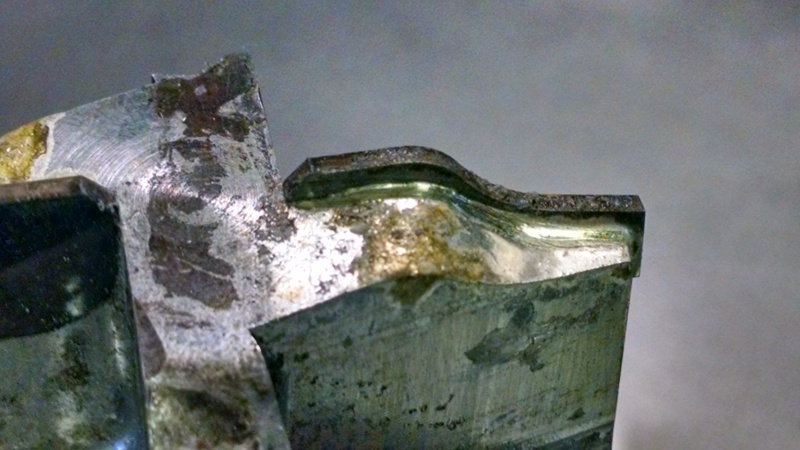

A client had been using an inexpensive imported induction heating system, but ran into quality issues that resulted in production down time. Consequently, they turned to THE LAB at Ambrell to develop the right solution for their application and enable the installation of a reliable EASYHEATTM induction heating system. The application involved heating steel cutting bits with diamond-carbide inserts for brazing and de-brazing. Cutting tools were the end product.

Ambrell's applications engineers determined that a 4.2 kW EASYHEAT would meet the client's objective of heating the part to 1400 oF (760 oC) within 25 seconds. A specially designed single-turn hairpin coil was developed for this heating application. Along with reliability, the modest size of the EASYHEAT is a benefit as it makes it easy to integrate the system into manufacturing processes such as this one.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...