Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

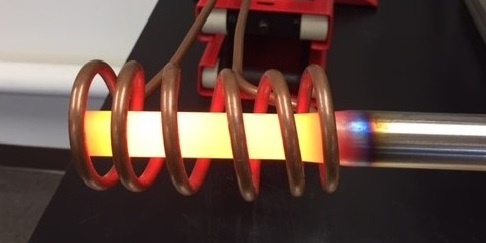

A tube manufacturer was designing a new process that involved annealing a stainless steel tube, and they turned to THE LAB at Ambrell to help. The client wanted to heat the tube with an 0.8”/20.3 mm OD to 1900 oF (1038 oC) within one minute. The applications engineers in THE LAB worked to design a solution based on their requirements.

More induction annealing application notes

An Ambrell EASYHEATTM 10 kW (150-400 kHz) induction heating system was determined to be the ideal solution given their time requirements. A custom-designed single position multi-turn helical coil was built to generate the required heating for the application. Temperature indicating paint was then applied to the tube, which dissolves when the part reaches the target temperature. It took 45 seconds to heat the tube to the target temperature for this annealing application, which met the client’s objective.

The client had previous experiences with THE LAB and turned to them once again because they wanted a partner that could help them take a concept to a working prototype. They turned to induction from Ambrell because it's rapid, flameless, repeatable and requires a minimal footprint in their manufacturing facility.

Do you have an application that might benefit from THE LAB's expertise? Let us know and we'll get the complimentary parts testing process started. Check out our annealing section to see more annealing applications and contact us today to discuss your heating application.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...