Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

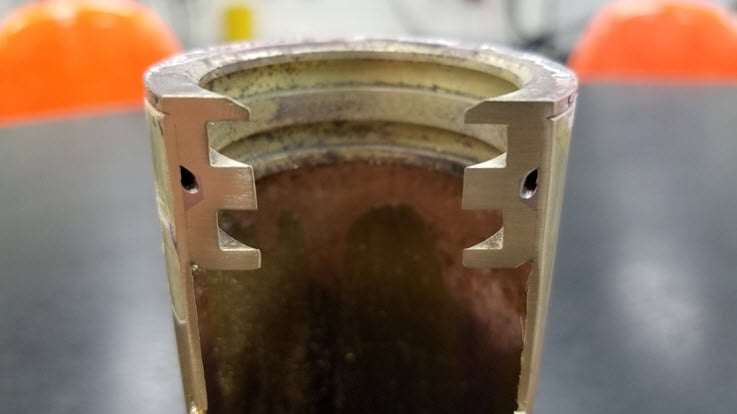

A manufacturer of sink products had been using a torch for brazing brass assemblies. However, repeatability had become an issue so they turned to THE LAB at Ambrell to test induction heating for their brazing application.

More brazing application notes

THE LAB determined that an EASYHEAT™ 6 kW, 150-400 kHz induction heating system with a custom-designed single position multiple-turn helical coil would be the right solution for their brazing application. It took two minutes to heat the 2”/51 mm OD brass assembly to 1425 °F (773 °C), meeting the client's time objective.

As already mentioned, repeatability was a critical factor as to why they turned to Ambrell induction heating. The client was seeing inconsistencies from torch operator to operator, so switching to induction resolved that issue. Induction was also fast, and it doesn't introduce a flame into the work environment, making it more comfortable and safe.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...