Removing Rubber Bonded to Steel Using Induction Heating

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

Processes

Processes: More

Processes: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Justyna Bakker

6/30/16 8:13 AM

Induction heating can effectively deliver localized heat to parts of virtually all shapes and sizes. Recently, our applications engineers from THE LAB in Europe tested a clamp annealing application using an EKOHEAT® induction heating system.

More induction annealing application notes

First, let's provide a little background. Annealing with induction is a process that involves heating a material above its re-crystallization temperature. It is commonly used to make a sample more workable through increasing its ductility and reducing its hardness.

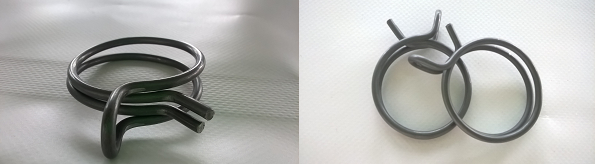

This application had challenging requirements: induction annealing the bended areas of only the steel hose clamps in 0.25 - 0.75 seconds per piece in batches of five. The temperature requirement was 350 °C (662 °F). After a series of complimentary tests from THE LAB, our engineers recommended a 15 kW system running at a frequency of 100 kHz.

Our induction heating solution will enhance the customer's productivity and throughput. Are you interested in putting induction technology to work at your plant? Just fill out this lab service request form below and experience first-hand how Ambrell's solutions can make the difference for your process.

Objective Removing rubber that has been permanently bonded to steel or other ferrous substrates can be a challenging and time consuming process....

In defense manufacturing, there is little margin for error. Components must meet exacting specifications, perform reliably in extreme environments,...

Overview When working with high-performance alloys like Inconel, achieving precise, repeatable heating is critical—especially in research and...