Objective

To heat ferrule and module assemblies for a soldering application in the fiber optics industry.

End Product

fiber optical device

Equipment

Ambrell EASYHEAT™ 1.2 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application

Materials

kovar ferrule, copper housing

Temperature

358 °F (180 °C)

Frequency

280 kHz

Testing

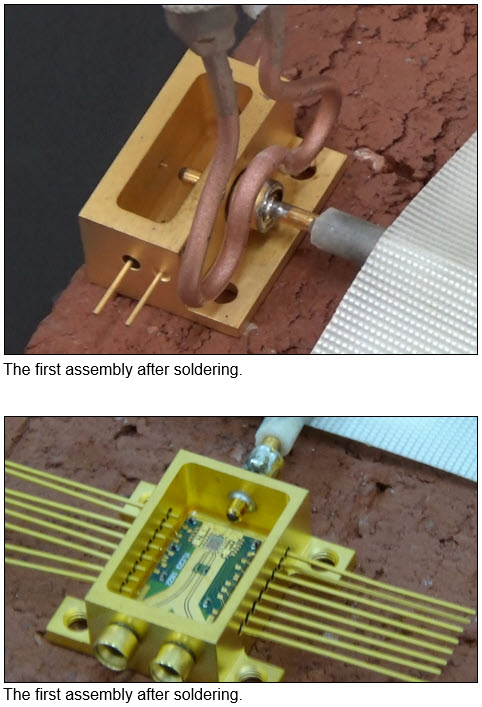

A custom-designed single position multiple-turn helical coil was built to generate the required heating for this application. A small amount of energy was used so that the client would have time to adjust the ferrule inside of the module while the solder is in a liquid state. It was observed that the first module soldered within a minute and the second module was soldered within three minutes.

This achieved the objectives required from the client’s process

Benefits

-

Repeatability: The client had been using a soldering iron and induction offers superior repeatability.

-

Speed: While speed was not of particular concern in this application, induction can offer superior speed compared to a soldering iron.

-

Part Quality: Superior repeatability means a more consistent result and enhanced product quality

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000