Objective

To heat copper tabs for bonding for a solar cell stringing and tabbing application

End Product

solar panel

Equipment

Ambrell EASYHEAT 1 KW, 150 kHz to 400 kHz solid state induction power supply, equipped with a remote workhead containing one 0.1 capacitor

A single-position solder pen induction heating coil designed and developed specifically for this application

Materials

Copper strips

Temperature

356 ºF (180 ºC)

Frequency

200 kHz

Testing

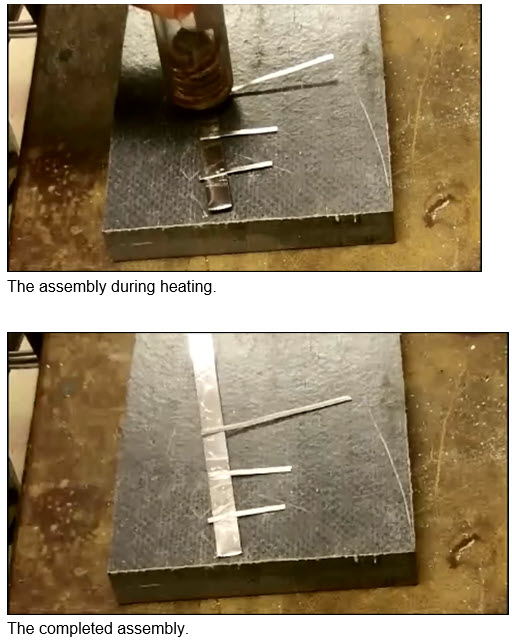

The coil assembly consisted of a ‘C’ core ferrite, and the copper coil was wound around the core. The heat time for this application was 1-2 seconds

Benefits

-

Speed: The heating process took just 1-2 seconds

-

Repeatability: Induction is a repeatable heating process, so a consistent result is achieved each time

-

Beneficial to surrounding substrate: Induction’s precision heating ensures there is less damage to surrounding substrates than you’d see from other heating methods

-

Efficiency: There is less heat loss and lower energy usage for this application with induction when compared to other heating methods

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000