Objective

To heat the customer supplied parts for a glass preform reflow application

End Product

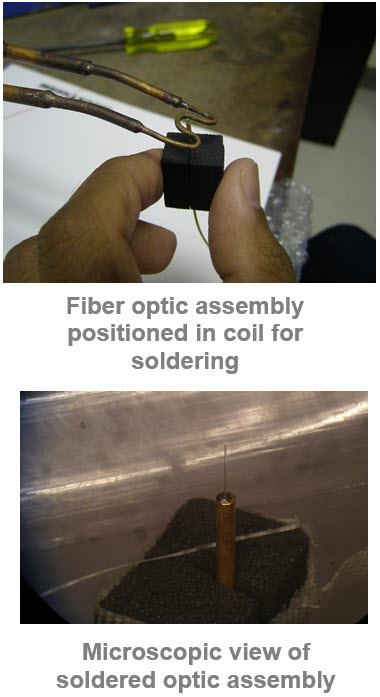

fiber optic assembly

Equipment

Ambrell 1.2 kW induction power supply, with a remote heat station containing one 0.66 microfarad capacitor.

An induction heating coil designed and developed specifically for this application.

Materials

Optical Fiber (0.007 in./ 0.178 mm.), Fiber Ferrule(0.051 in./ 1.3 mm.), Glass Solder Preform (0.047 in./1.2 mm.)

Temperature

450ºF (232ºC)

Frequency

379 kHz

Testing

A single turn channel “C” coil is used to generate the required heat pattern. The assembly is placed in the coil and power is applied for fifteen seconds. A heating time of 15 seconds will result in a good solder flow.

The customer is using a heating block with a heating time of up to 20 seconds. The customer is looking for a non contact heating process. The Ambrell 1.2kW power supply, along with the fifteen second heating time results in better glass flow and solder joint.

Benefits

-

Rapid localized heat only where needed

-

Repeatable, consistent results

-

Creates clean, controllable joints

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000