Objective

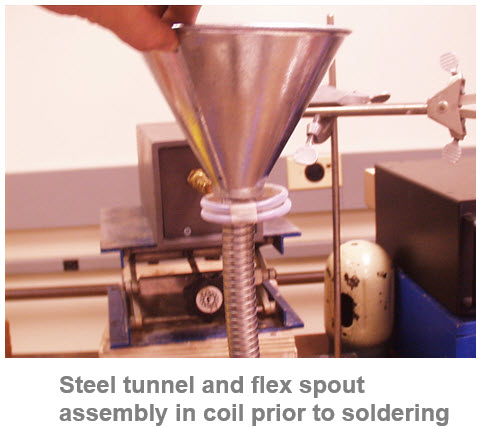

Soldering a tube and funnel assembly

End Product

tube and funnel assembly

Equipment

Ambrell 2kW induction heating system, equipped with a remote heat station containing two 0.1uF capacitors for a total of 0.2uF

An induction heating coil designed and developed specifically for this application.

Materials

A galvanized steel funnel (6.35 in./160 mm diam.),(4.65 in./118mm deep), a tin plated flex spout (0.092in./23.54mm diam.), flex and solder pre-forms

Temperature

400ºF ( 204ºC)

Frequency

254 kHz

Testing

A two-turn helical coil is used for this soldering application. The funnel is fluxed, and two solder performs are placed at the solder joint. This assembly is placed in the coil, and heated for eighty seconds to flow the solder and form the joint. The application is also done with a four position coil and soldering four parts simultaneously at 400º F ( 204ºC) for ninety seconds.

The customer wanted to shorten cycle times, in turn reducing energy output and man hours expended. With the use of Ameritherms’ products and technology, lab tests have confirmed the feasibility of this goal.

Benefits

Induction heating provides:

-

Non contact energy efficient heat without flame

-

Repeatable and consistent results

-

Precise and accurate placement of heat

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000