Objective

To heat a coaxial antenna assembly to 600°F within 2 seconds for a soldering application. The goal to improve on an existing procedure with a soldering iron which required 10 to 15 seconds.

End Product

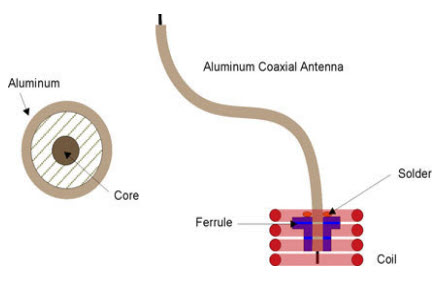

antenna

Equipment

Ambrell 1 kW power supply, remote heat station with one 1.2 µF capacitor and a specially designed induction coil.

Materials

.250” diameter aluminum antenna assembly, aluminum ferrule, solder paste, temperature indicating paint

Temperature

600°F

Frequency

333 kHz

Testing

Initial tests were conducted with temperature indicating paint to establish a heating profile and determine time-to-temperature. The solder paste was then applied to the antenna assembly and aluminum ferrule. RF power was applied for two seconds to heat and flow the solder joint.

Benefits

Consistent and repeatable results were achieved within the required two-second time frame. A close examination of the solder joint indicated that the solder flowed well and formed a good, solid joint.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000