Objective

Heat multiple joints on solar flex circuit strips to 500°F (260ºC) within ten seconds for a soldering application.

End Product

flex circuits

Equipment

Ambrell 1 kW induction heating system equipped with a remote workhead with one 1.2 µF capacitor

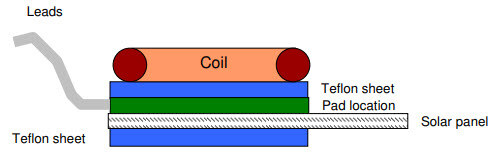

An induction heating coil designed and developed specifically for this application.

Materials

Flexible solar panel, Solder Plus Paste 63NC-A, 0.0625” (1.59mm) thick Teflon sheets

Temperature

500 °F (260ºC)

Frequency

278 kHz

Testing

A specially-designed induction coil is used to provide even heat in the area where the wires on the solar circuits overlap. A very light coat of solder paste is applied to the circuit connections and a small amount of pressure is applied to the Teflon sheets to hold the circuits together. Power is applied for 10 seconds to flow the solder paste and bond the wires to the flex circuits

Benefits

Induction heating provides:

-

Consistent and repeatable results

-

Non-contact clean heating

-

Flameless process

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000