Objective

Soldering three fuse caps simultaneously to reflow lead free solder and make a joint between the fuse cap and fuse wire guide

End Product

fuses

Equipment

Ambrell 10 kW induction heating system, equipped with a remote workhead containing two 1.0µF capacitors for a total of 0.5µF

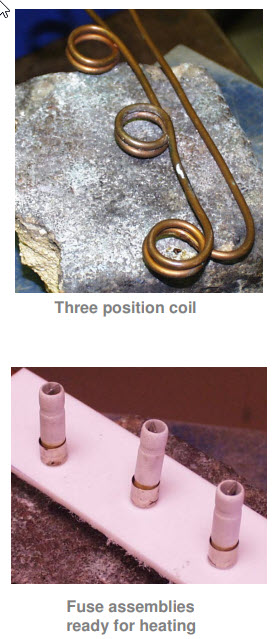

An induction heating coil designed and developed specifically for this application

Materials

Plated copper end caps 0.375” (9.5mm) OD x 0.375” (9.5mm) height, ceramic fuse tube 1.5” tall (38.1mm) , lead free solder preforms

Temperature

700 ºF (371 ºC)

Frequency

286 kHz

Testing

A three position two turn helical coil is used to solder three fuse caps simultaneously. The fuse assemblies are placed in the coil and the heat is applied in three cycles at 3.5 seconds per cycle to reflow the solder. On the production line the bottom caps are soldered first. The fuses are filled with sand and without flipping the assembly the top cap is soldered.

Benefits

Induction heating provides:

-

Consistent, repeatable results

-

Precise & accurate heat application

-

Hands-free heating that involves no operator skill for manufacturing

-

Even distribution of heating

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000