Objective

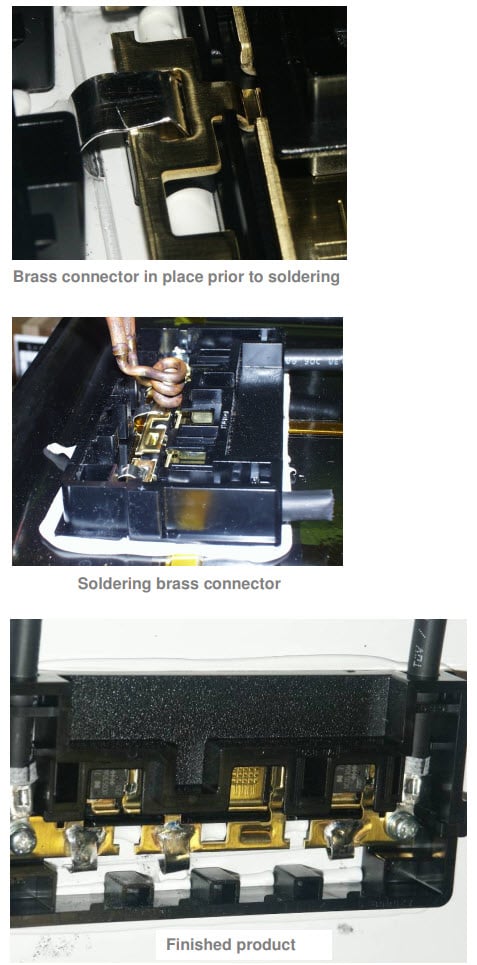

Solder three brass connectors one at a time in a solar panel junction box without affecting the components in the junction box

End Product

solar panel junction box

Equipment

Ambrell 4.2 kW induction heating system, equipped with a remote workhead containing one 1.0 µF capacitor.

An induction heating coil designed and developed specifically for this application.

Materials

Solar panel junction box, brass connectors, solder wire

Temperature

700 ºF (371 ºC)

Frequency

344 kHz

Testing

A three turn oval shaped helical coil is used to heat the connectors. A piece of solder wire is placed onto the joint area and each joint is heated separately for 5 seconds to solder the connector. The total process time is 15 seconds for the three joints.

Benefits

Induction heating provides:

-

Pinpoint accuracy deliver heating only to joint; does not affect surrounding components

-

Localized heat produces neat and clean joints

-

Produces high quality, repeatable results

-

Even distribution of heating

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000