Objective

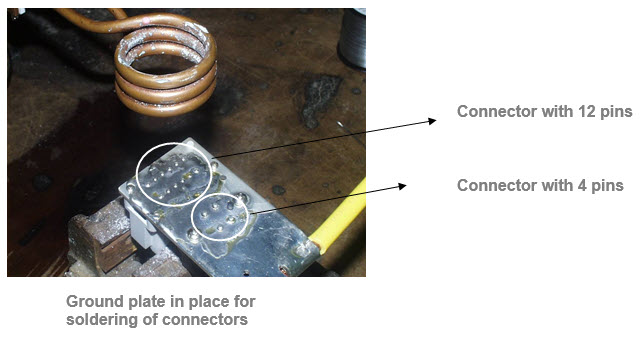

Soldering two connectors simultaneously to a tin plated copper ground plate

End Product

ground plate

Equipment

Ambrell 5 kW induction heating system, equipped with a remote workhead containing two 1.0μF capacitors for a total of 0.50 μF

An induction heating coil designed and developed specifically for this application.

Materials

Tin plated copper ground plate 4” x 1.75” (101.6mm x 44.45mm), 2 connectors, one with12 pins & one with 4 pins and 60/40 solder

Temperature

650 ºF (343 ºC)

Frequency

321 kHz

Testing

A three-turn helical coil is used to heat both sets of pins simultaneously. Power is applied for less than 20 seconds causing the solder to flow. A solder stick can be used but solder preforms work better.

Benefits

Induction heating provides:

-

Non-contact heat

-

Hands-free heating that involves no operator skill for manufacturing

-

Even distribution of heating

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000