Objective

To solder a kovar piece with glass insert into copper base and then desoldering same pieces for repair

End Product

photon light source

Equipment

Ambrell 9.0 kW induction heating system, equipped with a remote workhead containing two 1.5μF capacitors for a total of 0.75μF

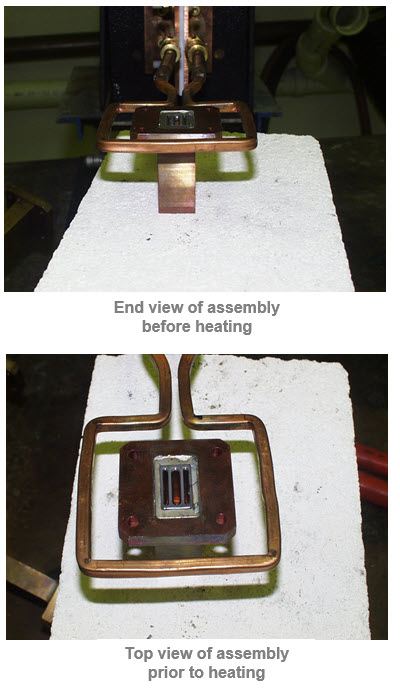

An induction heating coil designed and developed specifically for this application

Materials

Kovar piece with glass insert 0.9375” (23.8mm) diameter, 0.5625”(14.3mm) wide and a copper base 1.5” (38.1mm) square

Temperature

423ºF (217ºC) for soldering, 536ºF (280ºC) for desoldering

Frequency

350 kHz

Testing

A one-turn coil of square tubing is used to heat the copper and kovar insert with solder to 423ºF (217ºC) in 1.5 minutes. The copper heats slowly and expands so the kovar piece with glass drops in place and is soldered. Care is taken to cool the pieces slowly so that the glass insert does not break as the copper contracts. The desoldering application is for repair purposes. The soldered pieces are placed in the same coil and are heated to 536ºF (280ºC) for 2.5 minutes so the solder melts and pieces are separated while hot

Benefits

Induction heating provides:

-

Same equipment for both assembly and repair.

-

Hands-free heating that involves no operator skill for manufacturing

-

Uniform control of heat from part to part

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000