Objective

Heat connector assemblies for soldering

End Product

connector assembly

Equipment

Ambrell 2.4 kW induction heating system equipped with a remote heat station, containing two 0.66 µF capacitor.

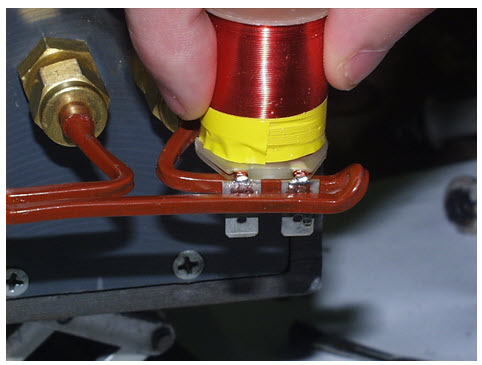

An induction heating coil designed and developed specifically for this application

Materials

Device assembly, tin-plated brass terminals, solder paste

Temperature

500*F (260*C) 5-7 seconds

Frequency

360 kHz

Testing

A single-turn helical coil is used to heat the solder paste. The connectors are placed inside the induction heating coil and RF power is applied for 5-7 seconds until the connector heats. Solder paste is applied to the joint in two ways, stick-fed or manually.

Benefits

Compared to using a manual soldering iron, induction heating precisely applies heat to for higher quality solder joints

This is ideal for integrating with an automated system. By stick- feeding the solder more aesthetically pleasing parts are produced.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000