Objective

To heat an aluminum tube for a shrink fitting application; the customer was seeking to replace their oven with induction heating

End Product

optical system

Equipment

Ambrell EASYHEAT 2 kW, 150-400 kHz induction heating system equipped with a remote workhead

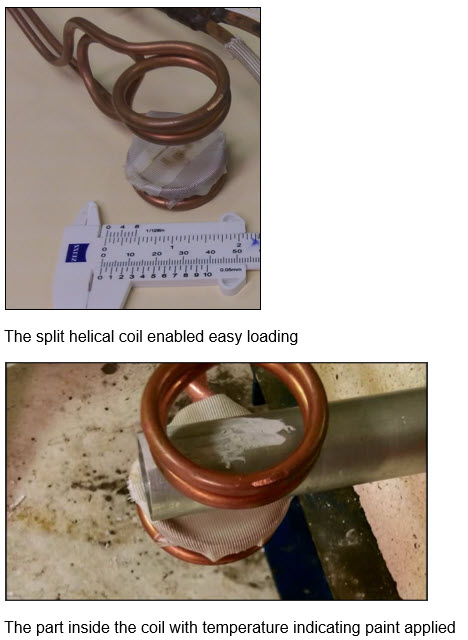

A single position four-turn split helical coil designed and developed for this application A multi-turn, special series-parallel induction heating coil designed and developed specifically for this application.

Materials

Aluminum tube (19”/483 mm length x 0.875”/22 mm outside diameter x .065”/1.7 mm wall thickness) & Temperature indicating paint

Temperature

437 ºF (225 ºC)

Frequency

235 kHz

Testing

(EASYHEAT 2 kW) the aluminum tube heated to temperature within 30 seconds. Shrink fitting then took place. This met the customer’s requirements for its process.

(EASYHEAT 4.2 kW) the aluminum tube’s heating time can be reduced to just 18 seconds. Should additional throughput be required, faster heating can be achieved with a higher power EASYHEAT power supply.

Benefits

-

Speed: The client needed a rapid heating solution to enable higher production levels

-

Energy efficiency: Induction is fast and it is instant on/off, presenting significant energy savings over an electric oven

-

Footprint: Induction requires a more modest footprint than an oven requires

-

Integration: Induction can be easily integrated into an automated process

-

Expertise: Ambrell and its applications team bring critical knowledge that comes with 10,000 plus installations of various applications and decades of applications experience

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000