Objective

To heat an aluminum motor housing to temperature to enable shrink fitting; induction will be used within an automated line.

End Product

motor housing

Equipment

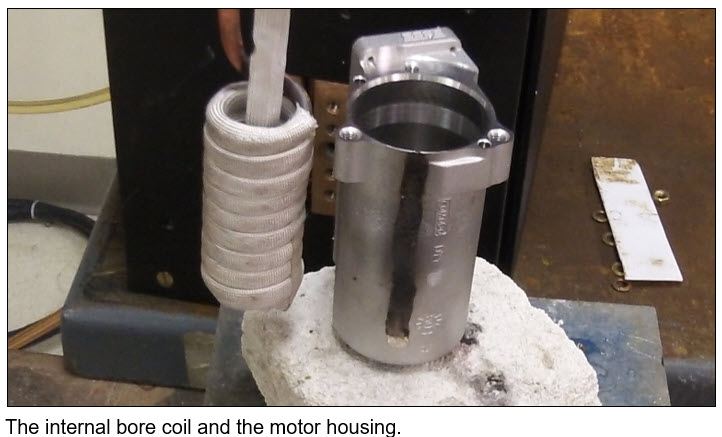

Ambrell EKOHEAT 45 kW, 50-150 kHz induction heating system equipped with a remote workhead containing eight 1.0 μF capacitors

A single position nine-turn internal bore coil designed and developed for this application

Materials

Aluminum housing (4”/102 mm tall with an ID of 1.9”/48 mm) & Temperature indicating paint

Temperature

464 ºF (240 ºC)

Frequency

71 kHz

Testing

The part was painted with temperature indicating paint that would melt to a clear color once it achieved the targeted temperature. The temperature indicating paint was also used to show balanced heating.

With 0.125” (3.2 mm) radial clearance, the EKOHEAT met the temperature requirements within the targeted seven second rate. The key in the application is to maintain a modest radial clearance as an increase will require more power, increased water flow, and a more complicated coil.

Benefits

-

Speed: The client needed a rapid heating solution to enable high production levels

-

Energy efficiency: Induction is fast and it’s instant on/off, presenting significant energy savings over an electric oven

-

Footprint: Induction requires a more modest footprint than an oven requires

-

Integration: Induction can easily be integrated into an automated process

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000