Objective

To heat an aluminum motor housing to 400 ºF (204 ºC) for a shrink fitting application

End Product

motor housing

Equipment

Ambrell EASYHEAT LI 7590 9kW, 150-400 kHz induction heating system equipped with a remote heat station containing two 1.0 μF capacitors

A single position eight-turn helical coil designed and developed for this application

Materials

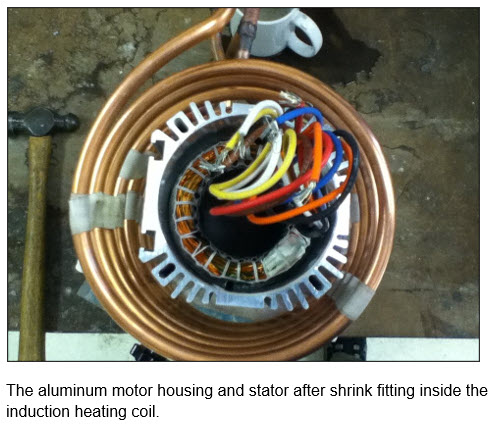

• 4.5”/114 mm outside diameter by 4”/102 mm inside diameter by 7.5”/191 mm tall aluminum motor housing • Stator

Temperature

400 ºF (204 ºC)

Frequency

208 kHz

Testing

Initial heat trials were conducted, and temperature indicating paints of 350 ºF (177 ºC) and 450 ºF (232 ºC) were applied. The part was heated to desired temperature and the stator was inserted into the housing. With the 9kW EASYHEAT LI power supply, the part can be heated to temperature within two minutes for this shrink fitting application.

Benefits

-

Part quality: The customer was using a cold press, but it was creating part defects. This was resolved with induction heating

-

Speed: The client tested an oven, but it took 40 minutes to heat it to temperature. Induction took just two minutes

-

Production rate: Thanks to the faster heating time of induction, they were able to achieve their targeted production rate

-

Repeatability: Induction’s fast, precise heating means the client can count on consistent results once it is implemented into their process

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000