Objective

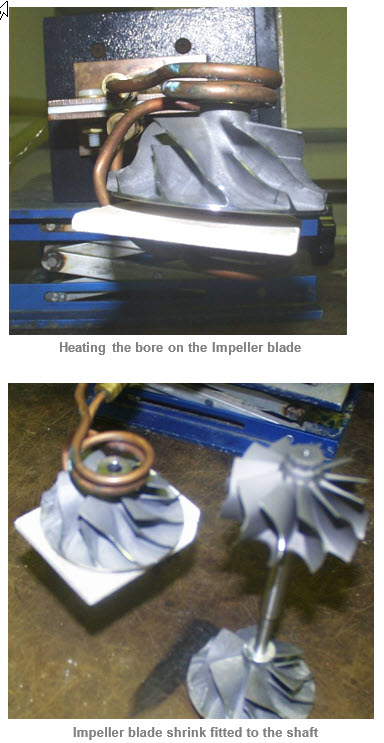

To heat aluminum impeller blades to 200 ºF (93 ºC) and shrink fit them onto shafts.

End Product

turbo charger

Equipment

Ambrell EASYHEATTM 3.5 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials

Aluminum impeller blades with a .28” (7.109 mm) bore, aluminum shaft

Temperature

200 ºF (93 ºC)

Frequency

255 kHz

Testing

A split two-turn helical coil is used to evenly heat the opening on the impeller blade. The impeller blade is heated for 20 seconds to reach the target temperature of 200 ºF (93 ºC). The impeller blades are then removed from the coil and slipped over the shaft to complete the shrink fitting application.

Benefits

• Accurate and repeatable results

• Reduced cycle time, lower consumable expenses

• Even distribution of heating

• Ease of integration into existing production lines

• Energy efficient

• Hands-free heating that involves no operator skill for manufacturing

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000