Objective

To heat steel parts on the inside diameter to shrink fit them into the casing

End Product

steel part

Equipment

Ambrell EKOHEAT 50 kW, 15-45 kHz solid state induction heating power supply with a workhead and coil specifically designed for this application

Materials

Customer supplied steel parts

Temperature

500 °F (260 °C)

Frequency

22 kHz

Testing

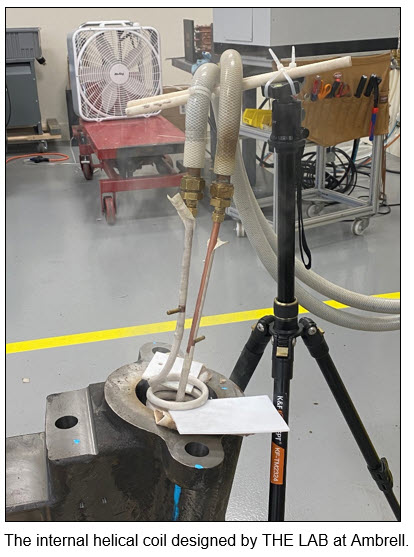

A specially designed multiple turn internal helical coil was used to provide the heat to the various steel parts. Initial tests were conducted to optimize the power delivered to the part and to understand the heating patterns achieved. After several changes and iterations on the coil setup, the process was optimized.

The time to heat to reach the target temperature was ten minutes

Benefits

-

Speed: Induction is typically a faster heating method for shrink fitting than alternative heating options.

-

Efficiency: Induction offers instant on/instant off heating and only heats the portion of the part that requires it, making it an efficient option for heating.

-

Reliability: The client can expect the same result in the same amount of time every time, making ideal for manufacturing processes that demand reliability and consistency

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000