Objective

End Product

mud pump

Equipment

Ambrell 250 kW, 10 kHz induction heating system, equipped with a remote workhead containing one 53.6μF capacitor.

An induction heating coil designed and developed specifically for this application.

Materials

Steel cylinder 10.625” (27cm) OD with a 2.625” (6.6cm) thick wall and 21.75” (55.2cm) long, liner 5.5” (14cm) OD and 26.375 (67cm) long

Temperature

900 ºF (482 ºC)

Frequency

7.8 kHz

Testing

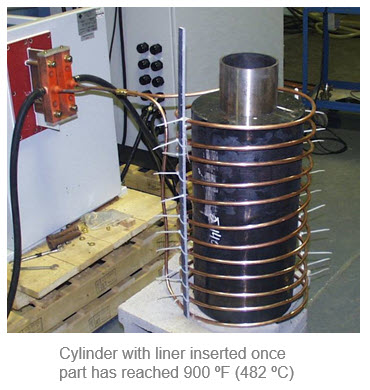

An eleven-turn helical coil is used to heat the cylinder. The cylinder is placed inside the coil and power is applied for 10 minutes to reach the temperature of 900 ºF (482 ºC). Once the temperature is reached the steel liner slides easily into the cylinder and the assembly is cooled to create the shrink fit

Benefits

Induction heating provides:

-

Faster heat cycle

-

Increases production rate versus furnace systems

-

No preheat cycle or controlled cooldown required, reduces energy cost

-

Even distribution of heating

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000