Objective

Heat aluminum bottle caps to 428ºF (220ºC) for curing the ink

End Product

Bottle caps

Equipment

-

Ambrell 30 kW induction heating system, equipped with a remote workhead containing eight 0.33µF capacitors for a total of 2.64 µF

-

An induction heating coil designed and developed specifically for this application.

Materials

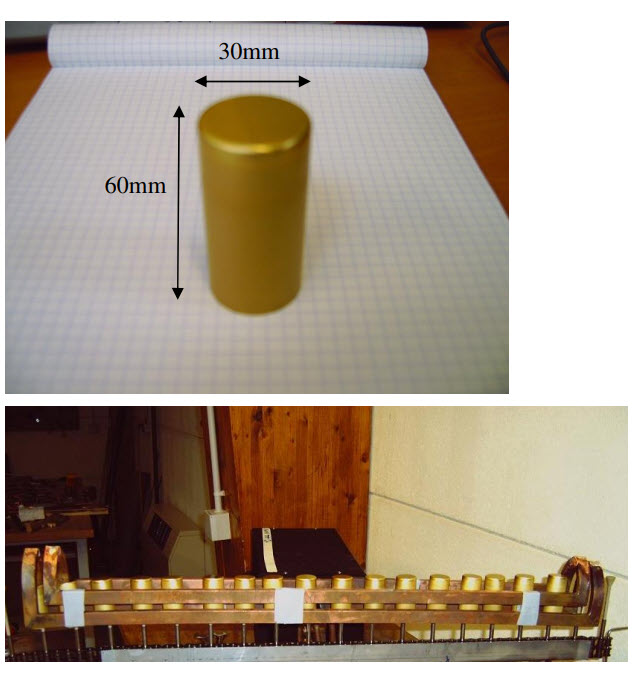

Aluminum bottle cap 2.36” (60mm) tall, 1.18” (30mm) diameter & 0.01” (0.3mm) thick

Temperature

428ºF (220ºC)

Frequency

73 kHz

Testing

A double channel coil is used for the ink drying application. Fifteen bottle caps are placed inside the coil and power is applied for 3 seconds to dry the ink.

Benefits

-

Increased production over hot air drying

-

Drastically reduced the drying floor space and exhaust requirements.

-

Hands free operation

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000