Objective

To heat-cure a Ceramic fiber

End Product

ceramic fiber

Equipment

Ameritherm 20 kW, 50-450 kHz solid-state induction power supply with a remote heat station containing two, 0.75 µF capacitors (total 0.375 µF). A custom designed induction heating coil.

Materials

-

Ceramic fiber 30,000 (9,145) ft(m)

-

Steel tube

-

Temperature indicating paint

Temperature

1300(700) ºF(ºC)

Frequency

100 kHz

Testing

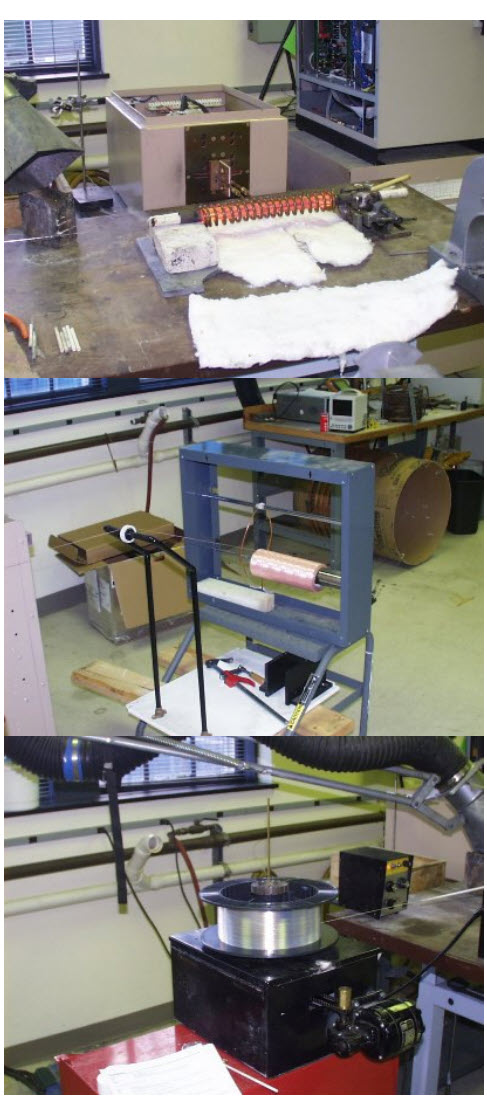

A special steel tube and coil combination is used to build an induction heating oven to cure the fiber on a continuous basis. The ceramic fiber travels in an alumina tube inside a hot steel tube. The ID of the alumina is 0.5(13) in(mm) to prevent any build up of the residue. Temperature indicating paint is used to ensure that the fiber is heated to 1300(700) F(ºC) at processing speed. The fiber can be heated to 1300(700) ºF(ºC) at a speed of 100(30.5) f/m(m/m) with this setup.

Benefits

-

Effective removal of the binder in the ceramic fiber

-

Ability to continuously process fiber with induction heat.

-

Other non-continuous heating methods don’t work.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000