Objective

To heat aluminum foil inside a plastic bottle for a bonding/cap sealing application; this application is for the food industry.

End Product

bottle cap

Equipment

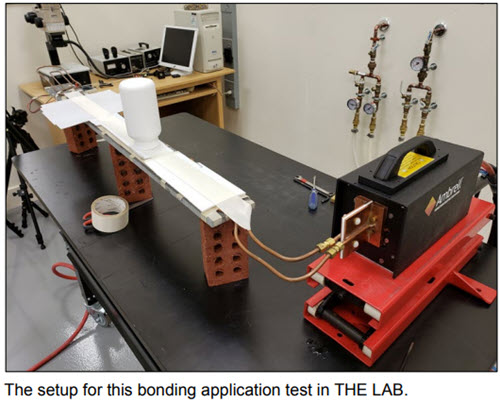

Ambrell EASYHEAT™ 4.2 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials

Aluminum foil sandwiched between the bottle and cap

Temperature

150 ° F (66 °C)

Frequency

150 kHz

Testing

A custom-designed single position multiple-turn pancake coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. Once a satisfactory pattern was achieved with the proper coil design, parts were traversed over the coil at a rate of about 45 bottles per minute. It was confirmed that the aluminum heated sufficiently to create a bond between the foil and the bottle, meeting the client’s objective.

Benefits

-

Speed: Induction met the client’s time requirements and is generally faster than other heating methods.

-

Throughput: Induction’s fast heating is conducive to production lines in the food industry thanks to its rapid heating and versatility.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000