Objective

Heat an aluminum seal for a plastic container

End Product

plastic container

Equipment

Ambrell EASYHEAT 1.2 kW, 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials

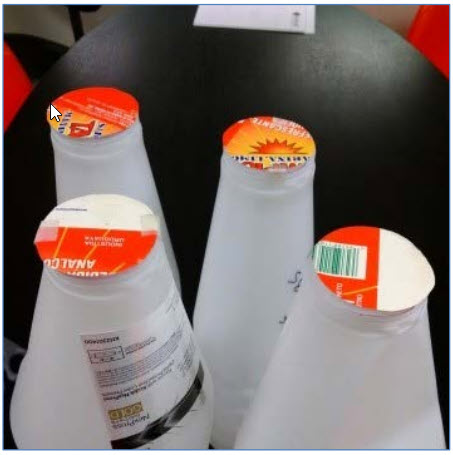

Plastic containers with aluminum seals

Temperature

250 oF (121 oC)

Frequency

250 kHz

Testing

A specially designed multiple-turn pancake coil was used for this heating application. Initial tests were conducted to optimize the power delivered to the part. After initial testing was completed, the part was placed into the coil and the power was turned on. The part reached temperature in just over one second.

Benefits

-

Speed: The client was using a different method for sealing the bottle. It required more time and was more costly.

-

Footprint: An EASYHEAT and a workhead required a minimal footprint, saving the client floor space.

-

Efficiency: Induction is an energy efficient method for sealing that fits well into a production process.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000