Objective

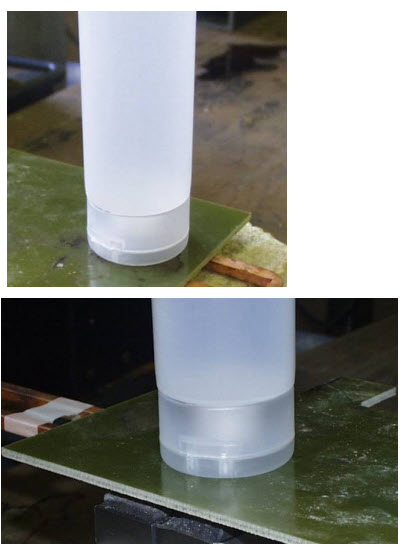

Heating a pre-assembled plastic tube and cap assembly with the aluminum foil seal in place

End Product

tube and cap assembly

Equipment

-

Ambrell 15 kW induction heating system, equipped with a remote workhead containing eight 1.0µF capacitors for a total of 8.0µF

-

An induction heating coil designed and developed specifically for this application.

Materials

Plastic tube and cap assembly with foil seal in place, 1.38” (35mm), 1.57” (40mm) and 1.97” (50mm) diameter

Temperature

N/A

Frequency

94 kHz

Testing

A 12” (304.8mm) single turn channel coil is used to heat multiple assemblies simultaneously. Power is applied for 2 seconds to complete the cap sealing application at the customers required run rate of 25’ (7.62m) per minute.

Benefits

-

Precise and accurate placement of heat

-

Repeatable results

-

Hands-free heating that involves no operator skill for manufacturing

-

Provides an air tight tamper proof seal

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000