Objective

To heat an aluminum in-cap laminate to a temperature of 350 ºF (177 ºC) to seal the laminate to the container.

End Product

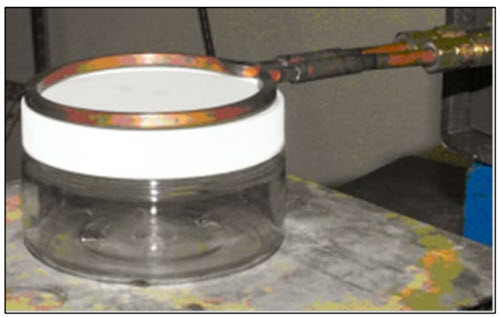

Lotion container

Equipment

Ambrell EASYHEAT™ 1.2 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials

Cap and laminate

Temperature

350 ºF (177 ºC)

Frequency

300 kHz

Testing

A single-turn helical coil generated the required heating pattern for this application. The induction system heated the assembled lid foil-container to the required temperature. The seal was achieved after ~1 second of heating.

Benefits

-

Speed: Induction met the client’s time requirements as it took just 1 second and is generally faster than other heating methods.

-

Economy: Power is applied directly to the foil; no energy is wasted heating the cap or the surrounding air or parts.

-

Automation: This heating system is easily integrated into automated processes

-

Control: The quality of the seal is ensured with the control of the heating system

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000