Objective

To bond steel cannulas

End Product

steel cannulas

Equipment

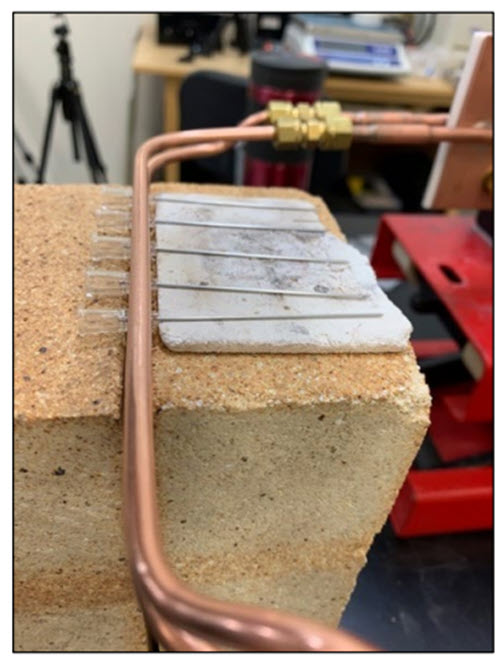

Ambrell EASYHEAT 4.2 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials

Stainless steel (various sizes)

Temperature

N/A

Frequency

340 kHz

Testing

Using the style and dimensions of the customer’s coil, a single turn channel coil was built to generate the required heating for this bonding application. Initial tests were conducted to determine whether the smallest of the cannulas would couple to the frequency of the EASYHEAT power supply. It was observed that they coupled to the induction field well and easily heated.

For each size cannula, the power delivered to the part was optimized to create a bond between the cannula and its bushing, without discoloring the steel of the cannula or causing the bushing to become opaque. Each size was successfully bonded at a rate of ten parts per 3.0 second heat cycle.

Benefits

-

Speed: Induction met the client’s time requirements.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating. This is particularly critical for medical applications like this one.

-

Footprint: Induction takes up a modest footprint compared to other heating methods, and the workhead can be placed away from the induction heating system.

-

Safety: There is no open flame with induction heating.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000