Objective

To heat steel wire embedded in an automotive rubber molding

End Product

automotive molding

Equipment

Ambrell EKOHEAT® 45 kW, 50-150 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials

Magnetic steel wire

Temperature

325 ° F (163 °C)

Frequency

85 kHz

Testing

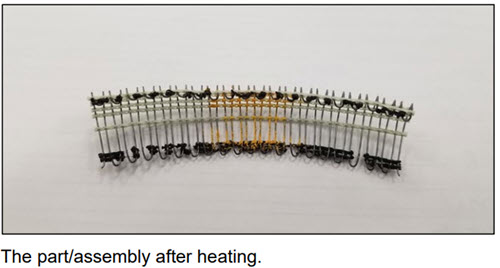

A custom-designed single position multiple-turn helical coil was built to generate the required heating for this bonding application. Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paint was then applied, which dissolves when the part reaches the target temperature. Ten rubber mold samples were heated at five different voltage settings (two samples per setting) to see if the wire bonded appropriately within the rubber mold. Testing from THE LAB confirmed the feasibility of the heating process for the customer.

Benefits

-

Speed: Induction met the client’s time requirements and is often faster than other heating methods.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating

Precision: Induction was able to heat the portion of the part (the two rubber strips) that required heating at the required temperature/ramp rate.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000