Objective

To heat steel tubes for an adhesive bonding application for a medical industry part

End Product

medical device

Equipment

-

Ambrell EASYHEAT 1.2 kW, 150-400 kHz induction heating system equipped with a remote workhead

-

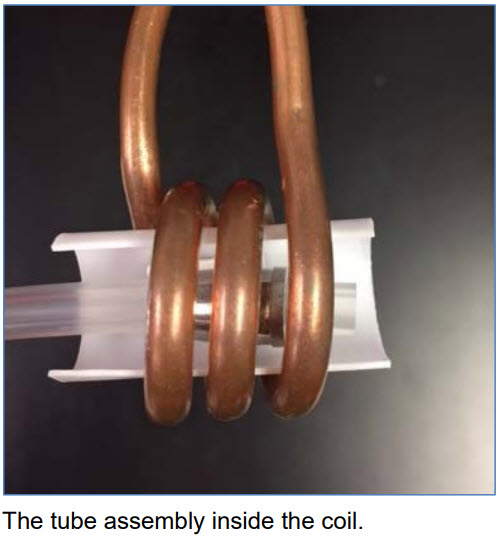

A single position multiple-turn helical coil designed specifically for this application

Materials

A stainless steel tube on a plastic tube

Temperature

392 ºF (200 ºC)

Frequency

392 ºF (200 ºC)

Testing

Initial tests were conducted to optimize the power delivered to the plastic tube assembly. Temperature indicating paint was then applied to the part, which dissolves when the part reaches the target temperature. It was observed that it took 5.0 seconds to heat the sample to temperature. After the part cooled to room temperature, it was compared to the customer-provided finished assemblies to confirm that the plastic was sufficiently bonded to the inside of the steel tube. Five assemblies were heated and the application was successfully proven out.

Benefits

-

Fast, Precise Heating: It took just five seconds with our lowest power unit to deliver the heat just where it was needed for this bonding application

-

Footprint: The EASYHEAT takes up a modest footprint, making it an easy addition to this client’s process

-

Repeatability: The client wanted the same result every time, which induction from Ambrell delivers

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000