Objective

To heat rubber gaskets with metal end rings to 550 °F (288 ºC) for a release/debonding application

End Product

subsea sealing

Equipment

-

Ambrell EASYHEAT 8.3 kW, 150-400 kHz induction heating system equipped with a remote workhead

-

A single position multiple-turn helical coil designed specifically for this application

Materials

-

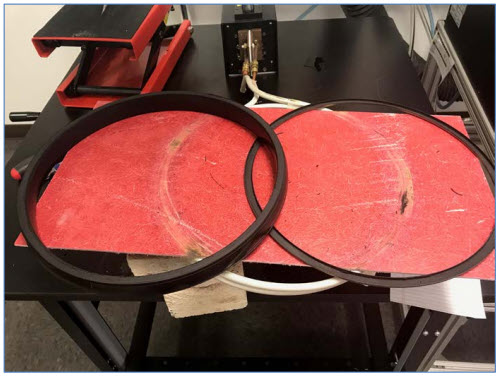

Rubber gaskets

-

Metal end rings

Temperature

550 ºF (288 ºC)

Frequency

231 kHz

Testing

Temperature indicating paint was applied to the part, which melts when the part reaches the targeted temperature. It took 30-40 seconds to heat one end of the sample to the required temperature. The part was rotated during heating by hand to normalize the heat produced and remove the effect of any localized hot spots. Feasibility of the application with an Ambrell induction heating solution was confirmed by THE LAB.

Benefits

-

Fast, Precise Heating: It took a modest amount of time to debond the rubber gasket from the metal end ring and heat was delivered only where it was needed

-

Innovation from THE LAB: Ambrell’s Applications Engineers were able to engineer the optimal solution for this application

-

Footprint: The EASYHEAT takes up a modest footprint, making it an easy addition into this client’s process

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000