Objective

To bond plastic with a steel gasket; the end product is the back bumper of a truck

End Product

Truck bumper

Equipment

-

Ambrell EASYHEAT LI 10 kW, 150-400 kHz induction heating system equipped with a remote workhead containing two 1.0 μF capacitors

-

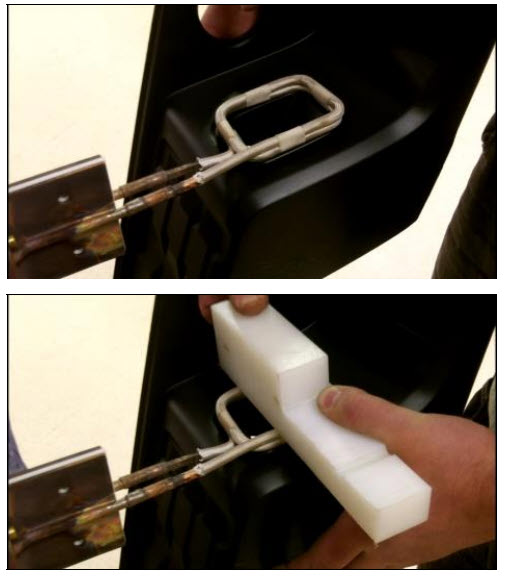

A single position, two-turn helical induction heating coil designed and developed specifically for this application

Materials

-

Plastic parts

-

Steel gasket

Temperature

500 ºF (260 ºC)

Frequency

300 kHz

Testing

The parts were assembled with the loaded steel gasket in between the mating surfaces. Manual pressure was applied to the two parts and the power was turned on. The power was on for approximately 45 seconds and the parts had just begun to outgas. The power was then turned off and manual pressure was applied for an additional 5-10 seconds. The application of pressure was imperfect and it’s likely the client will enjoy a superior heating rate in production. In the test environment, the parts heated to temperature within 45 seconds.

Benefits

-

Speed: Induction enabled rapid bonding

-

Footprint: Induction can easily be integrated into the client’s manufacturing process due to the EASYHEAT and its workhead’s modest space requirements

-

Repeatability: Induction is a highly repeatable process, so the client can expect the same result every time

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000