Objective

To heat a magnetic steel paint can for a de-bonding application

End Product

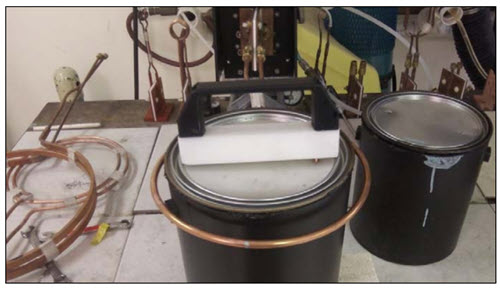

Paint can

Equipment

-

Ambrell EASYHEAT LI 3542, 4.0 kW, 150-400 kHz induction heating system equipped with a remote workhead containing two 1.5 μF capacitors

-

A single position, one-turn helical induction heating coil designed and developed specifically for this application

Materials

-

Customer supplied standard size paint can

-

Plastic lid with metal chime (10”/254 mm OD)

Temperature

450 ºF (232 ºC)

Frequency

231 kHz

Testing

The paint can, with temperature indicating paint applied, was placed into the coil and power was turned on. The steel began to heat, and the temperature indicating paint showed that the heat transferred inward about ¼” (6.3 mm) from the edge of the steel can. Torque force was applied and after 4-5 seconds the lid began to spin and was easily removed.

Benefits

-

Speed: Induction enabled rapid removal of the paint can lids

-

Process superiority: The alternative was to cut the cans, and the result would have been the cutting tool having a variety of paint on it; the goal of the process is to pour out paint to reformulate, so the unnecessarily mixing of paints is problematic

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000