Objective

To remove urethane from a steel insert (doffer pad).

End Product

Doffer Pad

Equipment

Materials

0.125” (3.2 mm) urethane coated steel disc (doffer pad)

Temperature

>800 ºF (>427 ºC)

Frequency

207 kHz

Testing

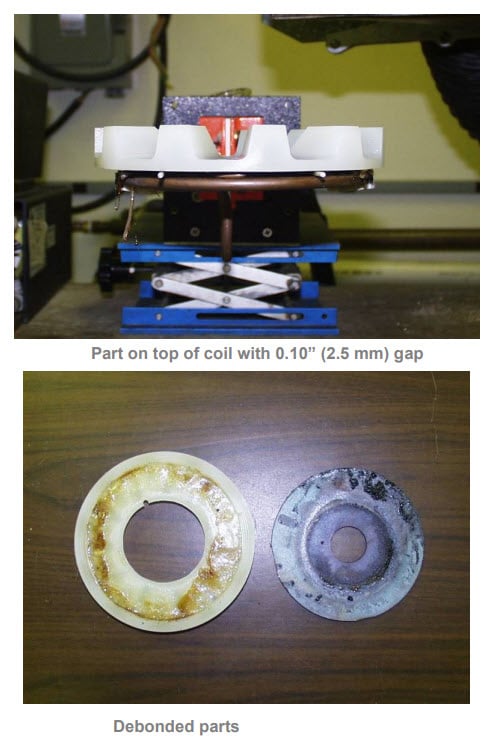

A three-turn pancake style coil was used to de-bond urethane from the steel disc. The part was placed onto two 0.10” (2.5 mm) thick ceramic rods on top of the coil and heated for 15 seconds. The urethane began to de-bond from the steel and was removed from the steel by hand.

This company was using a mesh rack in a burn off oven but wanted to see if induction might be a superior method for their debonding application.

Benefits

-

Hands-free heating that involves no operator skill for manufacturing

-

Reduced energy consumption

-

Consistent and repeatable results

-

Even distribution of heating

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000