Objective

To heat an electrically conductive ring gasket to seal the nylon halves of an activated-carbon fuel vapor module while reducing process time and cost.

End Product

Fuel Vapor Assembly

Equipment

-

Ambrell EKOHEAT 20kW power supply

-

Remote heat station with 0.66µF capacitance

-

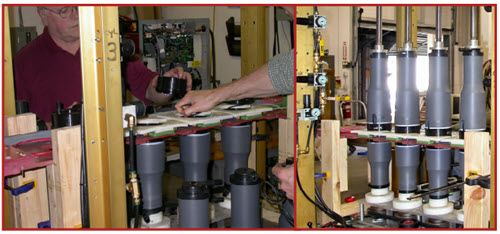

Specially-designed four-position induction coil

-

Customer-designed parts and test fixture

Materials

Nylon housing molds, conductive seal

Temperature

outer ~220°F , inner seal ~500°F

Frequency

165 kHz

Testing

Filter modules are assembled on the fixture with ring gasket. Pressure is applied to the modules, modules are rotated and induction heating is started. After 10-12 seconds, heating is halted and the modules are removed from the fixture.

Benefits

Seal integrity is confirmed.

-

Process times are reduced by more than 50%

-

seal material costs are reduced by ~90%

-

on-coil voltages are reduced by ~90%

-

arcing and related down-times are eliminated

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000