Objective

To heat two lens housings to 400 ºF (204 ºC)

End Product

lens housing

Equipment

Ambrell EASYHEATTM 5 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials

Metal housings mounted on a circuit board, lenses mounted in plastic holders.

Temperature

400 ° F (204 °C)

Frequency

350 kHz

Testing

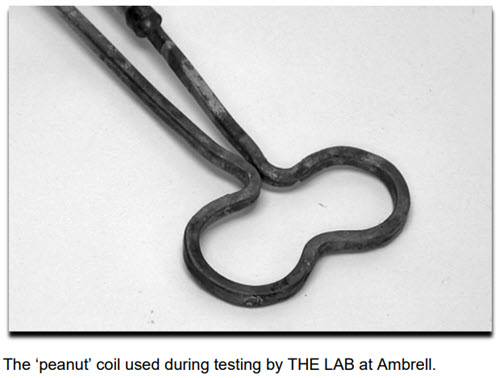

The assembly was placed on a non-conductive board to simulate the circuit board in the actual application. The area around the induction coil was very congested, with several electrical components in the immediate vicinity. A single-turn specially shaped induction coil was designed for this bonding application.

Initial tests were conducted using temperature indicating paint to establish heating profiles and time-to-temperature. Power was then applied until the temperature indicating paint melted. The metal-to-plastic assemblies needed 3.5 seconds to form a good bond.

Benefits

-

Improved processing quality by delivering uniform heat to two parts at once using a single-turn ‘peanut’ coil.

-

Localized heat enables easy alignment of optical components during final assembly.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000