Objective

To heat the stainless-steel substrate of a solar panel shingle in order to melt the polymer encapsulant, allowing two shingles to bond together with a 3-inch (76.2 mm) overlap.

End Product

Solar Panel Shingles

Equipment

Ambrell EASYHEAT TM 1.2 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials

3" (76.2 mm) by 10.25" (260.4 mm) section of a 21" (533.4 mm) solar panel shingle

Temperature

266 °F (130 °C)

Frequency

166 kHz

Testing

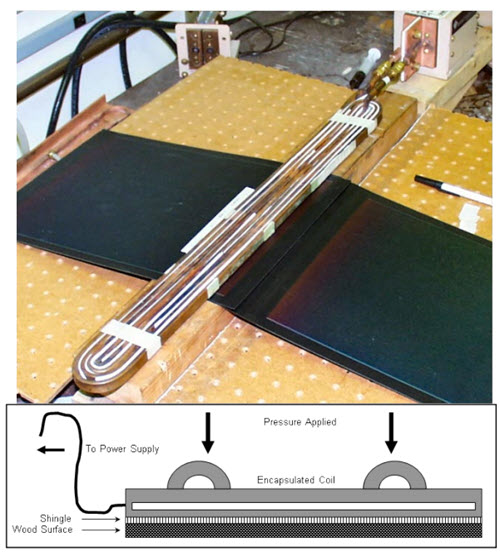

Stationary heating, with the coil located on the topside of the sample, was utilized to achieve uniform melt and adhesion. The shingles were overlapped according to requirements and placed on wood to simulate the installation on a roofing surface.

In addition, pressure was applied by pressing the water-cooled coil against the shingle to facilitate the bonding (see illustration). Tests were performed at several time-voltage settings. Testing resulted in excellent bond formation with the absence of encapsulant bubbling and only slight surface texture change.

Benefits

-

Induction delivers rapid, precise heating.

-

The process is highly repeatable, which leads to a dependable result.

-

The process prescribed by THE LAB at Ambrell resulted in an excellent bond formation

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000